iqf

Freezing by IQF technology

Products are frozen thanks to modern high-tech equipment using IQF technology. This method of “shock freezing” allows you to preserve most of the vitamins and useful substances in the product.

The process takes place in special “Unidex” freezing tunnels with a capacity of up to 60 tons per day. This is the highest quality of freezing, where each fruit is frozen individually.

static

Static freezing

This method of freezing is carried out in freezers or rack-type chambers.

It is used for products of industrial volumes, which are then processed in food industry enterprises.

This allows us to freeze up to 25 tons of fresh products per day.

Washing and drying

The process of preparing berries, fruits and vegetables always begins with washing and drying the products. Depending on the type of vegetables and fruits, we use soft or hard washing machines to facilitate this process.

Since vegetables and fruits have a delicate structure, our task is to gently remove dirt from the surface of the product without harming the fruit.

CLEANING

The process of deep cleaning of vegetables from dirt and sand, chemical residues, polishing and removing the skin or peel.

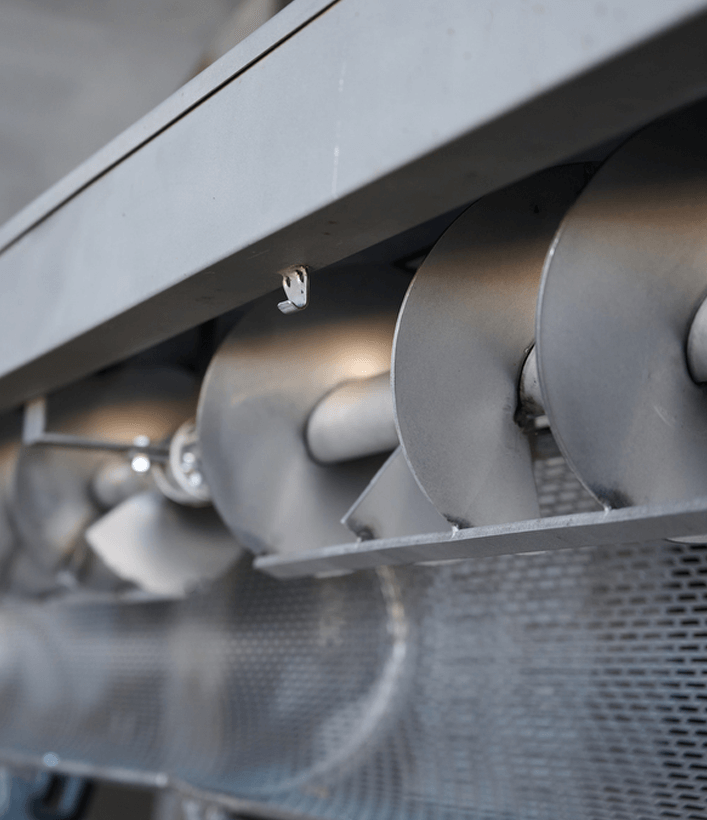

SHUCK

The process of winnowing, separating berries from stems, stalks, tails and leaves on an auger.

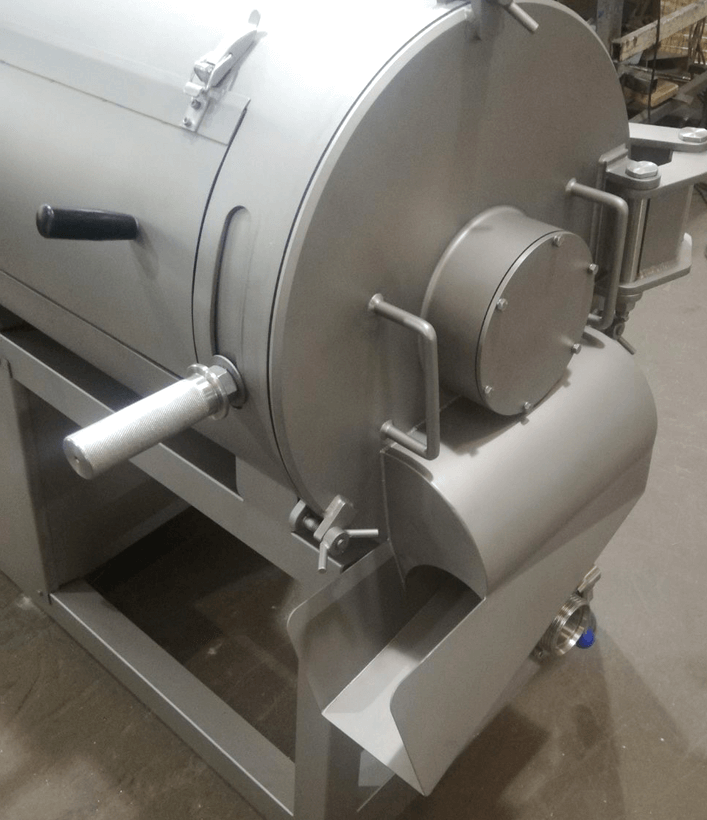

REMOVAL OF THE BONE OR PITH

Our pitting machines are designed to extract pits from fresh

cherries and plums. Our production capacity is up to 60 tons per day. The “HIGHBERRY” plant is also equipped with a machine for removing the core of the apple.

SCALDING

The process of rapid heating of products with steam gets rid of bitterness, sharp smell, allows you to preserve the colour and aroma of the product. Blanched products do not require further cooking.

FROSTING

The process of forming a thin layer of ice glaze on the surface of cruciferous vegetables, namely broccoli and cauliflower. This protects the product from freezing and disintegration of the inflorescence. This keeps the shape and colour fresh throughout the shelf life. After glazing, the products are well packaged in order to retain their high quality.

SLICING

Industrial shredding machines are designed for cutting a wide range of vegetables and root crops into cubes, strips, rings or slices. The shredding control function and a wide range of knives and grids allows to set up machines for cutting products of different calibres and thicknesses.

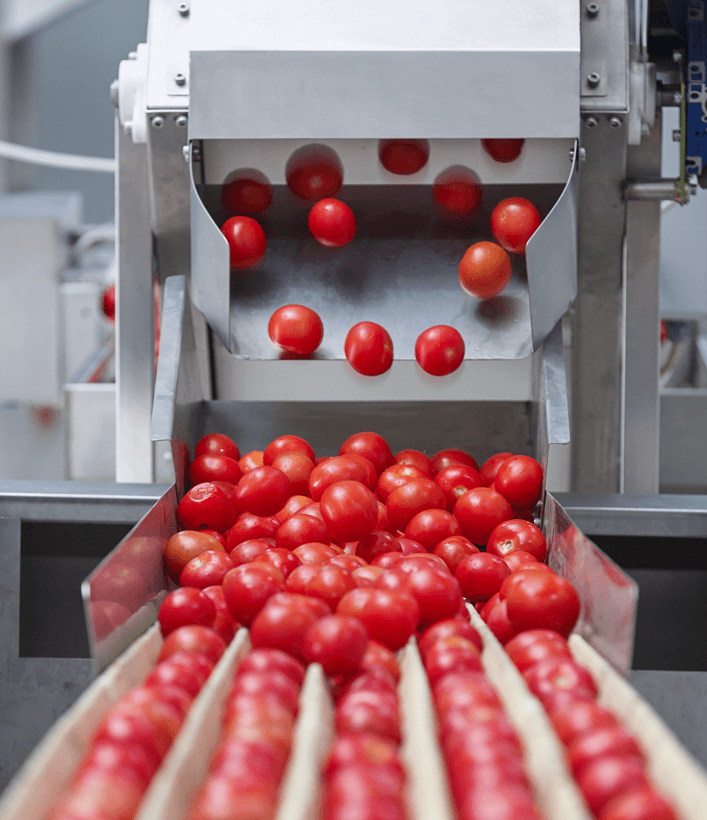

CALIBRATION

Our plant is equipped with industrial calibrators and conveyor belts for mechanical division into fractions of raw materials. This helps, in the calibration process, by screening fractions of berries, fruits and vegetables that are too small. As a result we are left with a calibrated product, sorted by shape and size, which is then sent to further processing and packaging.

MANUAL INSPECTION

Inspection is the most important step of the process, hence this is done manually. Professional inspection is done on conveyors with special lightning in order to guarantee high-quality and the successful execution of control measures, according to our standards.

PACKAGING

Packaging equipment is universal and it allows packing both fresh and frozen products of various types – vegetables, fruits, berries and mixtures, weighing anywhere from 0.4kg to 25kg.